How Membrane Switch Solutions Is Transforming Modern User Interfaces

How Membrane Switch Solutions Is Transforming Modern User Interfaces

Blog Article

Membrane Layer Switch Modern Technology: The Trick to Reliable and Affordable User Interfaces

Membrane switch technology has actually arised as an essential part in the layout of user interfaces, giving both integrity and cost-effectiveness across a varied variety of applications. As we explore the diverse benefits of membrane layer buttons, their potential for advancement increases inquiries concerning future applications and advancing fads.

Understanding Membrane Switch Modern Technology

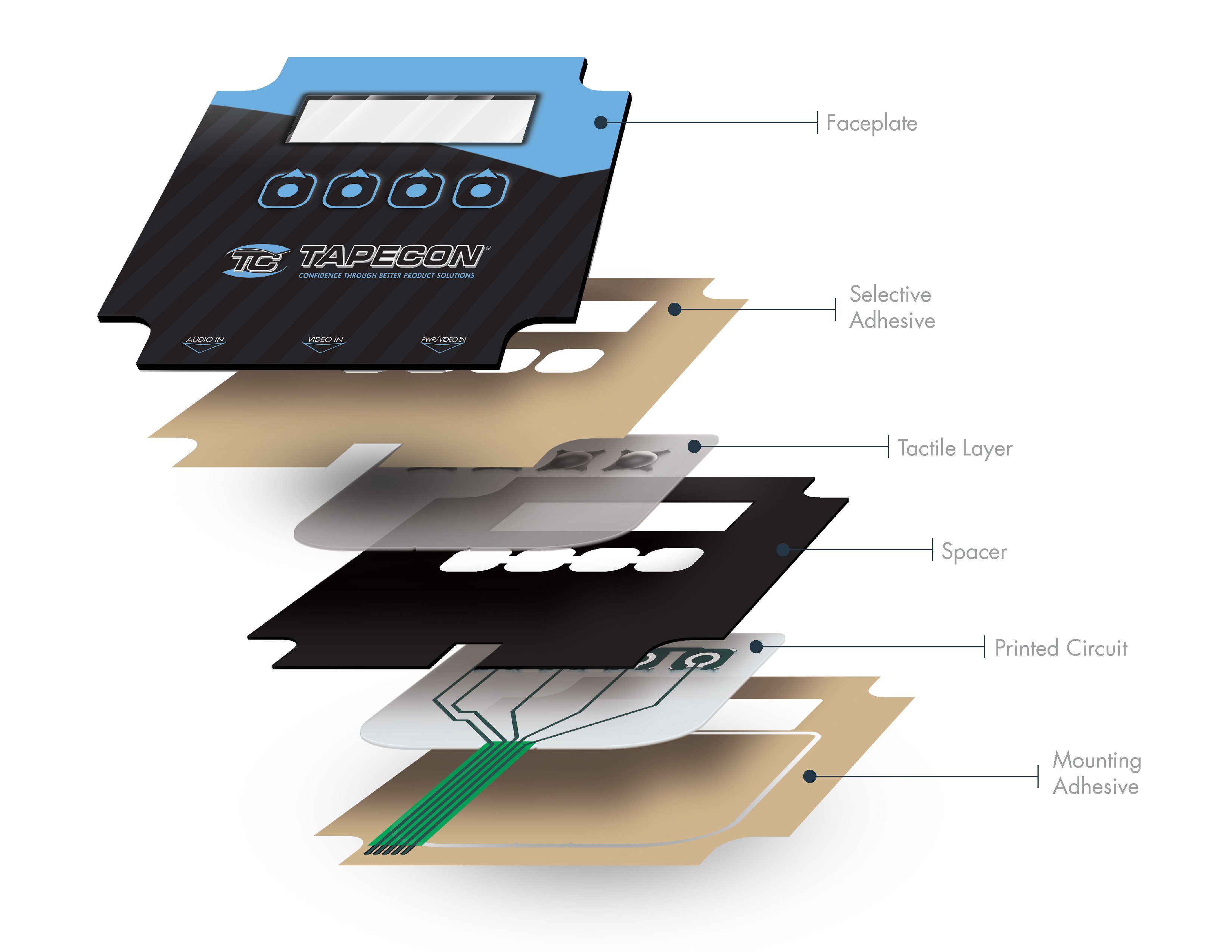

Membrane layer button technology is a commonly utilized user interface remedy in various electronic devices, supplying a smooth blend of functionality and design. This modern technology integrates numerous layers of products, typically being composed of a visuals overlay, spacer layer, and a circuit layer. The graphic overlay displays the interface aspects, while the spacer layer separates the circuit layer from the overlay until an individual activates a button.

When pressure is put on the overlay, the circuit layer completes the electrical circuit, sending out a signal to the tool. This system enables for various configurations, including responsive comments and backlighting options, boosting customer interaction. Membrane switches are generally produced making use of resilient products such as polyester or polycarbonate, ensuring durability and resistance to ecological variables like wetness and dust.

The flexibility of membrane changes allows their application in varied markets, consisting of medical devices, consumer electronic devices, and industrial controls. Their small design enables assimilation into space-constrained environments, providing an efficient interface without jeopardizing visual allure. Comprehending the complexities of membrane layer button innovation is important for producers and developers seeking to create trusted and effective human-machine user interfaces.

Secret Advantages of Membrane Buttons

While various user interface options exist, membrane layer switches deal unique advantages that make them a recommended option in various applications. One of the key benefits is their toughness; membrane layer switches are designed to withstand extreme environmental conditions, including dampness, dirt, and temperature changes, making certain durable efficiency. This resilience dramatically decreases the need for regular replacements, consequently decreasing total upkeep prices.

Furthermore, membrane buttons are light-weight and small, making them suitable for applications where space is restricted. Their low-profile design contributes to a streamlined look without jeopardizing functionality.

Cost-effectiveness is also a remarkable benefit, as the production procedure for membrane changes tends to be less costly compared to standard mechanical switches. This price, integrated with their reliability and convenience of setup, positions membrane layer changes as a useful solution for a wide variety of industries seeking effective and effective individual interfaces.

Applications Throughout Different Industries

Exactly how do membrane layer switches adjust to the diverse demands of different markets? Membrane layer button innovation is increasingly identified for its flexibility, making it linked here ideal for a large range of applications across several industries. In the clinical field, membrane layer buttons are used in diagnostic tools and client surveillance devices, where their longevity and ease of cleaning are essential for maintaining health standards. The vehicle sector employs these buttons in control panels and control panels, offering a streamlined visual while ensuring easy to use procedure.

In customer electronic devices, membrane layer buttons provide a compact option for remotes and home appliances, boosting individual experience with instinctive style. Furthermore, the industrial field leverages membrane switches for machinery control panels, gaining from their resistance to extreme settings, such as dampness and dirt.

Army and aerospace applications also utilize membrane switches for their reliability and ability to withstand extreme conditions, making sure functional performance in essential situations. Furthermore, the food and beverage industry takes on these switches for automated systems, where cleanliness and ease of operation are vital. Eventually, membrane layer switches are tailored to meet the distinct demands of each industry, proving their essential duty in contemporary technology interfaces

Design and Modification Choices

In the realm of membrane switch technology, layout and personalization alternatives play a crucial function in improving Look At This functionality and user communication. These switches can be customized to satisfy details operational needs and visual preferences, making them functional elements in numerous applications.

Among the primary modification choices is the layout of the switch itself, which can be made to fit unique interface and ergonomic considerations. By adjusting the form, size, and plan of switches, makers can create user-friendly designs that help with ease of usage. Additionally, the unification of different shades and graphic overlays permits branding and improved exposure, ensuring that individuals can rapidly recognize functions.

Additionally, membrane layer switches can be engineered with various responsive feedback systems, such as elevated buttons or audible clicks, to boost the user experience. Different products can also be chosen for durability and environmental resistance, resolving variables such as moisture, temperature level variations, and chemical direct exposure.

Inevitably, the substantial layout and modification options available in membrane layer button modern technology encourage businesses to produce customized remedies that not only meet functional requirements however also line up with their branding and functional demands.

Future Fads in Membrane Switches

As membrane button modern technology remains to develop, future patterns are significantly concentrated on enhancing user experience and integrating innovative capabilities. One substantial fad is the assimilation of touch-sensitive and capacitive modern technologies right into typical membrane layer switches. This advancement enables even more user-friendly individual interfaces, giving responsive responses while keeping a streamlined layout.

Another emerging trend is the usage of eco-friendly products, driven by the expanding need for sustainable manufacturing practices. Producers are seeking to reduce their carbon footprint by utilizing recyclable substratums and low-impact inks, lining up with worldwide sustainability goals.

In addition, the surge of the Web of Things (IoT) is prompting the incorporation of smart features into membrane layer buttons. Boosted connection choices will enable tools to connect with each various other, permitting for smooth combination into broader systems.

Additionally, advancements in printing innovations, such as electronic printing, are permitting greater layout adaptability and personalization. This allows makers to produce detailed styles and lively web link shades cost-effectively.

Conclusion

In final thought, membrane layer switch modern technology represents an important technology in individual interface design, using significant advantages in resilience, personalization, and cost-effectiveness. As innovations proceed to arise, particularly in touch-sensitive interfaces and lasting products, the potential for membrane layer switches over to enhance customer experience and functionality remains appealing.

Report this page